Hoobkas ncaj qha muab Turbine Roj Lim Ntawv - Kev lag luam tsis-woven lim ntawv rau Kev Txiav kua - Great Wall

Hoobkas ncaj qha muab Turbine Roj Lim Sheets - Industrial tsis-woven lim ntawv rau Txiav kua - Great Wall Paub meej:

Daim ntawv lim dej tsis yog woven

Cov ntawv lim dej tsis-woven uas peb lub tuam txhab tsim tawm yog siv los lim cov hlau me me, hlau sludge thiab lwm yam dross hauv cov kua txiav, emulsion, sib tsoo kua, sib tsoo kua, rub roj, dov roj, txias kua, ntxuav kua.

Thaum yuav cov ntawv lim dej, muaj ob lo lus nug uas yuav tsum tau piav qhia meej:

1. Txheeb xyuas cov khoom siv thiab qhov tseeb ntawm daim ntawv lim dej

2. Qhov ntev ntawm daim ntawv lim dej thiab lub cheeb sab hauv ntawm lub qhov chaw koj xav tau los ua daim ntawv lim dej rau hauv lub hnab lim dej, thov muab daim duab loj).

Peb cov ntawv lim dej tsis-woven Zoo

1. Lub zog tensile siab thiab cov coefficient me me ntawm kev hloov pauv. Jessman lim ntawv siv cov txheej txheem fiber netting thiab tsim cov khoom txhawb nqa los txhim kho lub zog tensile thiab khaws lub zog pib thiab lub zog siv yeej tsis hloov pauv.

2. Ntau yam kev raug thiab ua haujlwm tau zoo. Kev sib xyaw ua ke ntawm cov khoom siv tshuaj fiber thiab zaj duab xis polymer tuaj yeem ua tau raws li qhov xav tau sib txawv ntawm cov neeg siv.

3. Cov khoom siv lim dej feem ntau tsis raug cov roj lag luam xeb, thiab yeej tsis hloov cov khoom siv tshuaj lom neeg ntawm cov roj lag luam. Nws tuaj yeem siv tau feem ntau hauv qhov ntau ntawm -10 ° C txog 120 ° C.

4. Lub zog siab thiab ntsug, tiv taus kev tawg zoo. Nws tuaj yeem tiv taus lub zog kho tshuab thiab qhov kub ntawm cov khoom siv lim, thiab nws lub zog tawg ntub yuav tsis txo qis.

5. Muaj qhov porosity loj, tsis yooj yim lim dej, thiab muaj peev xwm lim dej tau zoo. Ua kom cov lim dej zoo dua thiab ua kom lub sijhawm ua haujlwm luv dua.

6. Muaj peev xwm tuav cov av qias neeg thiab txo cov roj zoo. Nws siv tau rau kev sib cais roj thiab dej, ua kom cov roj tshuaj siv tau ntev dua, txo cov khoom siv lim thiab txo cov nqi lim.

7. Cov ntaub ntawv lim dej ntawm ntau qhov dav, cov ntaub ntawv, qhov ceev thiab qhov tuab tuaj yeem hloov kho, tsim nyog rau ntau qhov chaw ua haujlwm.

Thov saib phau ntawv qhia txog daim ntawv thov kom paub ntxiv.

Cov kev ua tau zoo ntawm daim ntawv lim dej

| Qauv | Tuab (hli) | Qhov hnyav (g/m2) |

| NWN-30 | 0.17-0.20 | 26-30 |

| NWN-N30 | 0.20-0.23 | 28-32 |

| NWN-40 | 0.25-0.27 | 36-40 |

| NWN-N40 | 0.26-0.28 | 38-42 |

| NWN-50 | 0.26-0.30 | 46-50 |

| NWN-N50 | 0.28-0.32 | 48-53 |

| NWN-60 | 0.29-0.33 | 56-60 |

| NWN-N60 | 0.30-0.35 | 58-63 |

| NWN-70 | 0.35-0.38 | 66-70 |

Qhov hnyav grams:(ib txwm) 20, 30, 40, 50, 60, 70, 80, 90, 100, 120. (Tshwj xeeb) 140-440

Loj:500mm—–2500mm (qhov dav tshwj xeeb tuaj yeem hloov kho)

Yob ntev:raws li cov neeg siv khoom xav tau

Dov sab hauv qhov:55mm, 76mm, 78mm lossis raws li cov neeg siv khoom xav tau

Lus Cim:Tom qab xaiv cov khoom siv ntawm daim ntawv lim dej, nws yog qhov tsim nyog los txiav txim siab qhov dav ntawm lub lim dej, qhov ntev ntawm yob lossis sab nraud, cov khoom siv thiab sab hauv ntawm lub raj ntawv.

Daim Ntawv Thov Ntawv Lim

Kev ua tshuab sib tsoo

Feem ntau siv rau cylindrical grinder / internal grinder / centerless grinder / surface grinder (lub grinder dej loj) / grinder / honing tshuab / iav grinder thiab lwm yam CNC roller grinders, txiav kua, sib tsoo kua, sib tsoo kua, honing kua thiab lwm yam roj industrial Class filtering.

Kev ua hlau thiab hlau metallurgy

Nws yog siv los lim cov emulsion, coolant thiab dov roj hauv cov txheej txheem ntawm cov phaj txias-dov / kub-dov, thiab nws yog siv ua ke nrog cov lim dej siab tsis zoo xws li Hoffmann.

Kev ua tooj liab thiab txhuas

Nws yog feem ntau siv los lim cov roj emulsion thiab dov roj thaum lub sijhawm dov tooj liab / txhuas dov, thiab siv ua ke nrog cov lim phaj precision.

Kev ua cov khoom siv hauv tsheb

Nws feem ntau yog siv ua ke nrog lub tshuab ntxuav thiab (lub siab zoo, lub siab tsis zoo) daim kab xev lim dej los lim cov kua ntxuav, kua txias, kua txiav, thiab lwm yam.

Kev ua cov kabmob

Xws li cov kua lim dej txiav, cov kua sib tsoo (siv), cov kua honing, emulsion thiab lwm yam roj kev lag luam. Siv rau hauv kev kho dej phwj tuaj Kev lim dej suav nrog cov pas dej phwj tuaj, cov pas dej kais dej, thiab lwm yam, cov tshuab lim dej hauv nruab nrab, lossis siv ua ke nrog cov khoom siv lim dej.

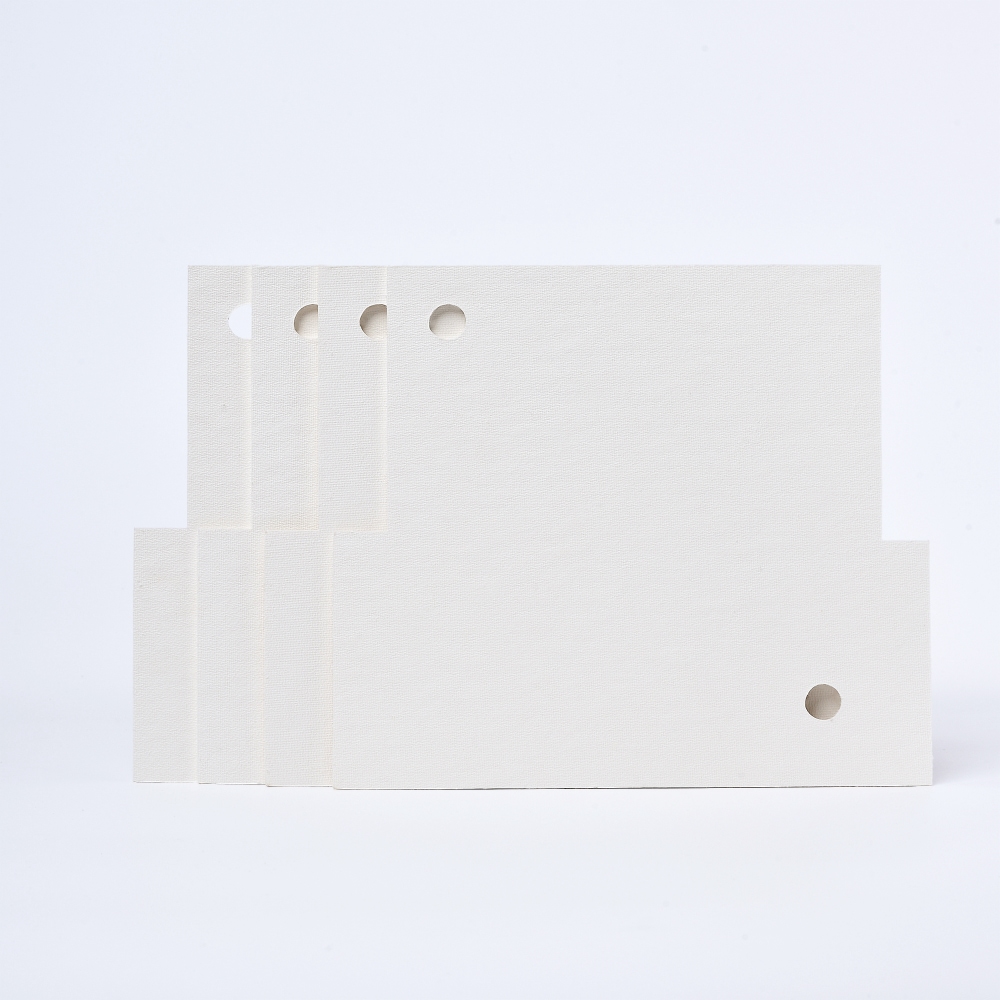

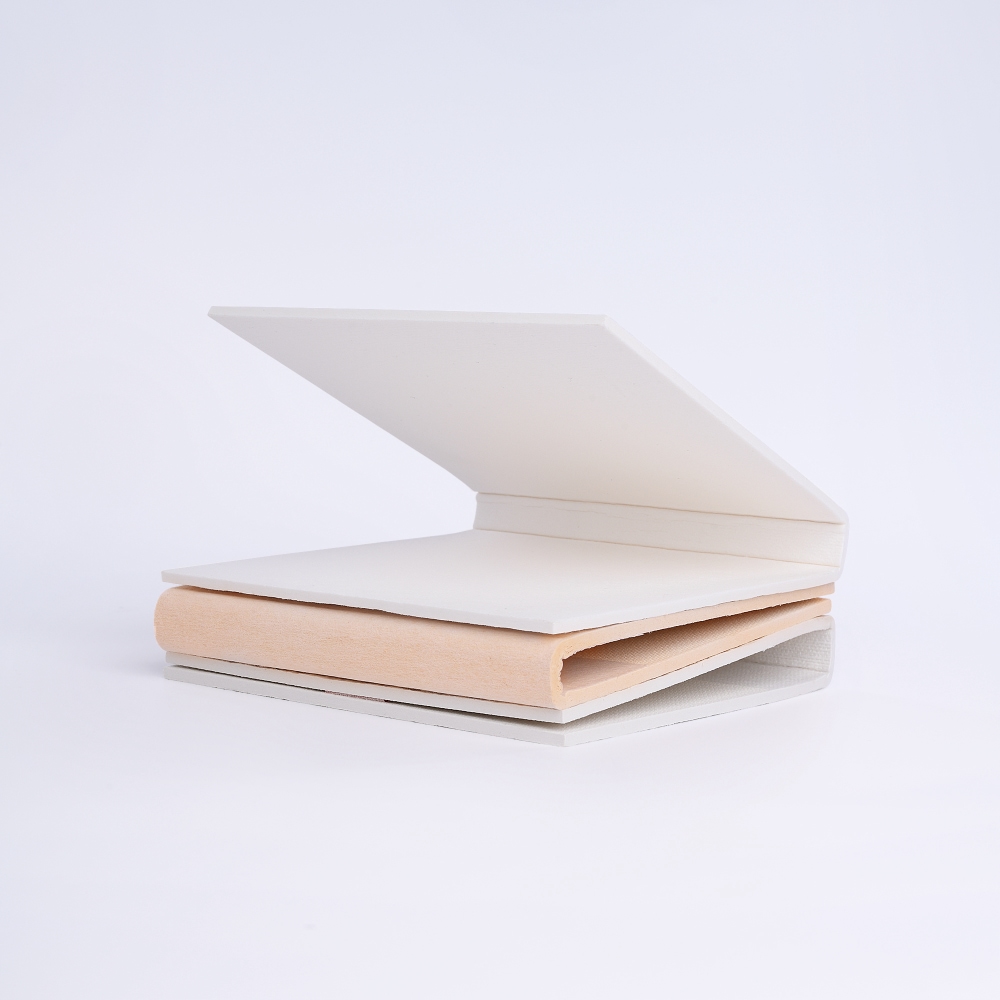

Cov duab qhia txog khoom:

Cov Lus Qhia Txog Khoom Siv:

Peb yuav ua txhua yam kev rau siab kom zoo tshaj plaws thiab zoo meej, thiab ua kom peb cov haujlwm sai dua rau kev sawv ntawm qib thoob ntiaj teb qib siab thiab cov tuam txhab thev naus laus zis siab rau Lub Hoobkas ncaj qha muab Turbine Roj Lim Ntawv - Kev lag luam tsis-woven lim ntawv rau Kev Txiav Kua - Great Wall, Cov khoom yuav muab rau thoob plaws ntiaj teb, xws li: Palestine, Brisbane, Las Vegas, Khoom tau dhau los ntawm daim ntawv pov thawj tsim nyog hauv tebchaws thiab tau txais tos zoo hauv peb txoj kev lag luam tseem ceeb. Peb pab neeg kws tshaj lij engineering yuav npaj txhij los pab koj rau kev sab laj thiab tawm tswv yim. Peb kuj tseem tuaj yeem xa koj cov qauv dawb kom ua tau raws li koj cov lus qhia. Kev siv zog zoo tshaj plaws yuav raug tsim los muab cov kev pabcuam thiab cov kev daws teeb meem zoo tshaj plaws rau koj. Yog tias koj xav paub txog peb lub tuam txhab thiab cov kev daws teeb meem, thov hu rau peb los ntawm kev xa email rau peb lossis hu rau peb tam sim ntawd. Txhawm rau kom paub peb cov kev daws teeb meem thiab kev lag luam. lossis ntau ntxiv, koj tuaj yeem tuaj rau peb lub Hoobkas kom pom nws. Peb yuav tos txais cov qhua los ntawm thoob plaws ntiaj teb rau peb lub tuam txhab. lossis tsim kev lag luam. kev zoo siab nrog peb. Thov koj xav tias dawb los tham nrog peb rau kev lag luam. thiab peb ntseeg tias peb yuav qhia qhov kev paub zoo tshaj plaws txog kev lag luam nrog peb cov tub lag luam txhua tus.

Tus neeg muag khoom no muab cov khoom zoo tab sis tus nqi qis, nws yog ib qho chaw tsim khoom zoo thiab tus khub lag luam.